Construction and Demolition waste (C&D waste) is created during the demolition of structures, which, pursuant the waste-hierarchy (EU-Richtlinie 2008/98/EG), are to be reused, recycled, utilized or disposed of.

In order to achieve the best possible utilization, C&D waste material has to be differentiated and sorted by single-origin and waste-category (Ordinance on the List of Wastes – AVV). In order to clarify whether and how the individual pieces of C&D waste are to be recycled and re-used as substitutes, process chain analyses are highly significant. They begin with the actual C&D waste at hand, focus on material that could potentially be recycled and integrate its use into a new construction product. The necessary treatment and manufacturing processes involved in the recycling materials are influenced thereby by both the quality of the C&D waste as well as the quality requirements vis-à-vis the recycling material used in the new construction product (Bimesmeier et al. 2020, Gruhler & Schiller 2022).

Process Chain Analyses

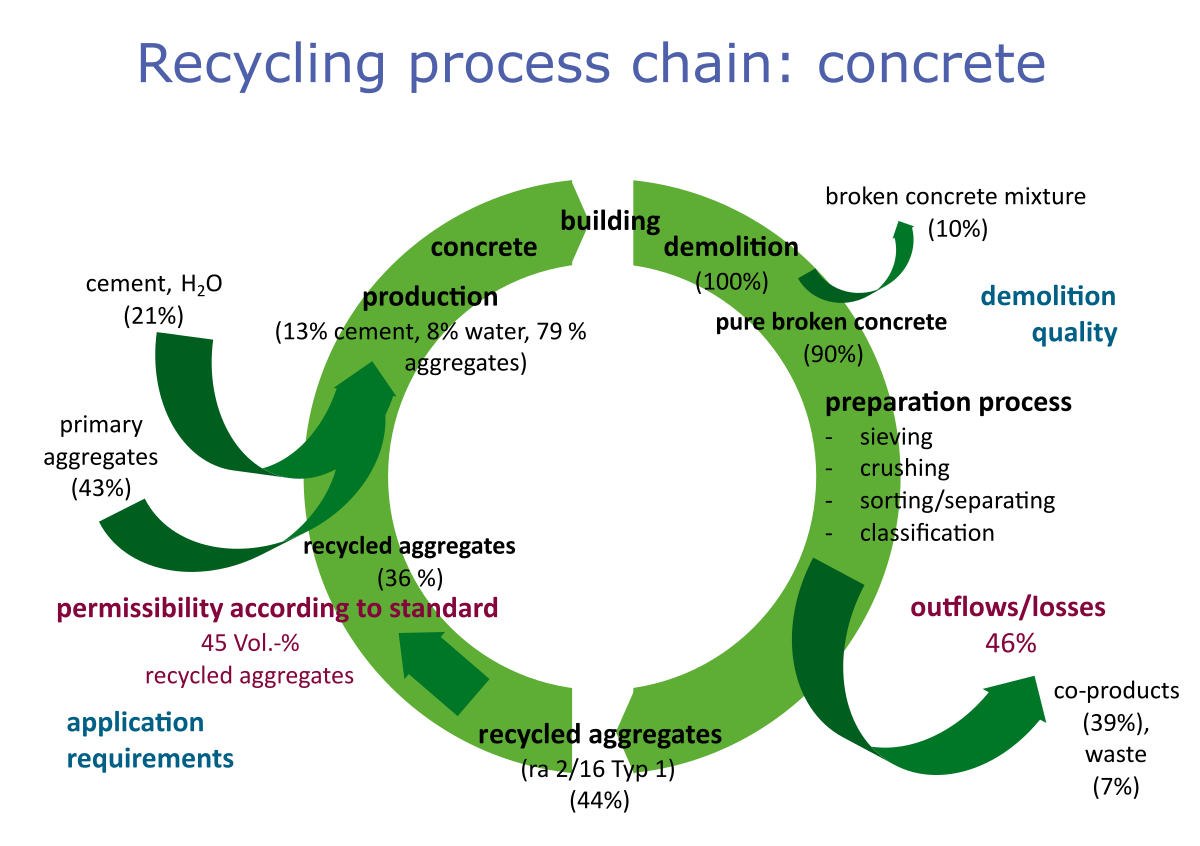

Process chain analyses - from C&D waste to the use of the recycled material in a new building product application - enable estimates to be made of changes in the quantities and qualities of the material flows along the recycling process as well as the associated energy expenditure and resulting emissions.

The example of the process chain for concrete shows that recycled aggregate can be obtained from pure concrete crushed material, which is suitable for the production of concrete in building construction. Thus, 44% recycled aggregate is produced from 100% concrete crushed material (pure and mixtures); the rest is 39% recyclable by-products and 7% waste.

The process chain analyses are based on building material data, the raw materials they contain and the resulting waste categories. They enable actors from the construction and recycling planning sector or the regional planning to simulate recycling measures or (secondary) raw material conservation scenarios, as well as to design, discuss and test potential business models.

The thought-processes behind the process chains have not yet been established within the construction sector; typically, recycling is carried out on demand.

Production of recycled aggregates without a specific commission and treating them on the enterprise premises is uneconomical.

Thus, recycling enterprises bemoan the lack of demand, and planning/construction contractors/construction companies lament the lack of supply regarding recycling materials (BMBP-Federal Ministry for Education and Research project INTEGRAL).

At the same time, recycling is a relevant measure for completing cycles within the construction sector, thus saving (i.e. conserving) natural resources. Applications for material cadastres on the basis of construction data have proven this in case studies (e.g. Schiller et al. 2022).